FAQ

- How long can I keep Dover Chemical’s glue ?

Dover Chemical’s glue can last between 3 to 4 weeks when kept at 30°C. During long holidays, you should either fill-up your storage tank if the glue is still fresh or empty it out altogether. If you keep glue level low in a large storage tank during holidays, the amount of heat from sun radiation onto storage tank will exceed the heat capacitance of glue causing the glue temperature to rise, its lifetime shortens and it may harden upon your return from holidays. - How do I save on glue consumption ?

You can save on glue consumption by reducing the mix size, for example at less than 100 kgs/pot, so that your gluemix can be completely useful without wastage. We have many success stories educating our customers to save on glue consumption that resulted with less wastage, cleaner production area and reduced cost. - How does high moisture content (M.C.) affect my panel’s formaldehyde emission ?

When moisture content in wood is high, methylene linkages formed during curing process can reverse into methylol afterwards and subsequently causes an undesirably high formaldehyde emission from your wood panel. This mechanism known as hydrolysis is responsible for many rejected shipment of panel products when panel producers were less informed. Dover Chemical, strong on the chemical side of the industry, during the past decade have been actively educating our panel customers and save them from such misfortune. - Can I solve blister problem by using Dover Chemical’s glue ?

Dover Chemical’s glue can solve your blister problem as long as you practice good control on veneer’s M.C. (for plywood), use our catcher to produce low emission product (for plywood), add melamine resin into your gluemix (for plywood), control M.C. of core layer and surface layer of your chips (for particleboard) or fibre (for MDF). - What are the common problems found with the use of rubberwood to make wood panels ?

Compared to albasia wood, rubber wood is more susceptible to fungus attack, contains higher amount of natural formaldehyde hence it emits higher formaldehyde from its panel product, and requires a higher temperature during hotpress. Collecting on our vast experience with a wide variety of wood species, we have solved these problems by providing customized solutions to our customers who use rubberwood. - How does hotpress time and hotpress temperature affect my wood panel’s formaldehyde emission ?

By increasing hotpress time and temperature, curing will shift to the right of the reaction and result with lower formaldehyde emission in your panel product. Temperature setpoint is limited however by the wood cellular structure, and moisture content in the press system. - How do I determine formaldehyde emission ?

Determination of formaldehyde emission should be done under a controlled manner in a laboratory. The method involves conditioning of the sample, placing the sample in a desiccator with pure water at the bottom, and test in an environmental chamber under a tight control of 20⁰C±0.5⁰C temperature and 65%±0.5% humidity for 24 hours. Formaldehyde emission from the sample is collected by pure water in desiccator during this time and checked for its value using a spectrophotometer. It is well known that our laboratory is the preferred reference for our customers who wish to cross-check their results although our report is limited only to the samples sent to us. - What are the five most important factors that will determine the level of formaldehyde emission from my wood panel ?

Hot press temperature, hot press time, wood species, veneer thickness, and glue molar ratio. - How do I calculate pressure from my press machine ?

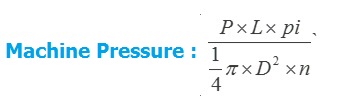

Formula:

pi : Desired pressure for hotpress or coldpress n : Number of piston D : Diameter of each piston P x L : Surface area of plywood - What is the difference among UF, MF, MUF, PF and PVAc glues ?

UF, MF, MUF and PF are thermosetting glues and PVAc is a thermoplastic glue. The type of monomers and raw materials that make up the glue gives their respective names and each has a different production process:

UF : is made from urea and formaldehyde from condensation polymerization reaction MF : is made from melamine and formaldehyde from condensation polymerization reaction MUF : is made from melamine, urea and formaldehyde from condensation polymerization reaction PF : is made from phenol and formaldehyde from condensation polymerization reaction PVAc : is made from vinyl acetate monomer from addition polymerization reaction - Where does Dover Chemical’s resin find its application ?

Dover Chemical’s resin is used in woodbased panels and insulation products. Our UF glue of many varieties meet all our customer requirement for U-type grades panels. Our MF glue is proven for its quality to produce very dimensionally stable panels fit for kitchen set, window frame and bathroom and was tested to withstand exterior conditions under rain and sun for a year. Our PF glue finds its way into concrete panels, swimming pool decking and passes the water-boiling test and cyclic tests. Finally our PVAc glues find their way into the wood industry, paint industry and some chooses it as their intermediate product to produce more variety of paper adhesion applications. Please see Emulsion under a different category of this website for our other glue products that find their way into many other applications of your day-to-day life. - What causes blister ?

Blister, an unwanted defect in woodbased processing, is caused by high moisture content in wood veneer (or fibre and chips in MDF and PB respectively). During hotpress, if your temperature is too high or hotpress time is too long, this moisture turned into saturated steam is trapped within the panel and is unable to escape from the side of the panel resulting with deformation on the panel surface called blister. If you apply too high pressure during hotpress, it prevents escape of steam from the side of the panel in a similar manner and causes blister too. Likewise, if glue spread is excessive you will introduce more water into the gluing system and causes blister by the same mechanism as above. - Why is my panel twisted ?

Twist is a dimensional deformation of a panel product that is often apparent only after a few days from production. Twist is caused by an uneven moisture level between the wood panel and its storage environment. If your wood panel is too dry or too wet, moisture tends to migrate into or out from your panel from one side of the panel that is unobstructed causing it to expand unevenly and twist either downward or upward. Use of melamine resin can be helpful to reduce such deformation but we prefer and we advocate to our customers to choose a more cost effective solution viz. by controlling moisture especially if the panel is meant to be sold as U-type grade only. - Why do we need to control MC of veneer ?

High moisture content is the main reason for product defect in wood based panels. When MC is too high, of an immediate consequence is blister during production; and of an eventual but more painful consequence is failure to meet formaldehyde emission level when your product reaches your buyer or distributor. On the other hand, when veneer is too dry you will face pre-cure problem whereby a large portion of the glue spread onto veneer has exhausted of its reactivity before hotpress. This in turn causes increase of glue consumption and lower bonding quality. Control of MC between 8% and 12% is a good practice in panel processing and you should not allow MC to climb to above 16%. From our experience, we have seen attempts to alter the production system to cater for MC veneer at above 16% by using more melamine resin, or adding MDI. But in the end these methods has proven to be more costly than by properly controlling the MC of veneer. - What is the effect from free formaldehyde in glue ?

Free formaldehyde in glue will react with free urea, free melamine or free phenol. Free formaldehyde will boost the speed of reaction during curing process but on the other hand it also shortens resin lifetime to a certain degree, depending on the amount of methylol present in the glue. - Why does the resin has a strong and pungent odour?

The strong and pungent odour from resin comes from free formaldehyde. - How does veneer thickness affect the requirement for gluemix viscosity ?

For a thin veneer (face/back), you will need a more viscous gluemix and a lower glue spread such that your gluemix does not penetrate into the already thin veneer. For a thicker veneer (core), you will prefer a less viscous gluemix in order to even out the gluespread across the surface without consuming too much glue. - Sometimes I observe some agglomeration in my gluemix. What are they ?

Powders such as your additives and hardeners has not dispersed completely in the gluemix due to inadequate mixing. - I have found some hardened glue at the bottom of my storage tank. How do I prevent this from happening again ?

When your tank circulation is not good, it creates dead zone that retains old resin during each top-up of new lots. The old resin gells locally at the bottom of tank and eventually hardens. We recommend conical bottom for a complete drain-out, bypass circulation line or scheduled cleaning to minimize wastage of glue.